Advancing technology plays an important role in everyday life. From phones and televisions, to kitchen appliances and vehicles — we all use technology and often seek out the latest and greatest models.

Advancing technology plays an important role in everyday life. From phones and televisions, to kitchen appliances and vehicles — we all use technology and often seek out the latest and greatest models.

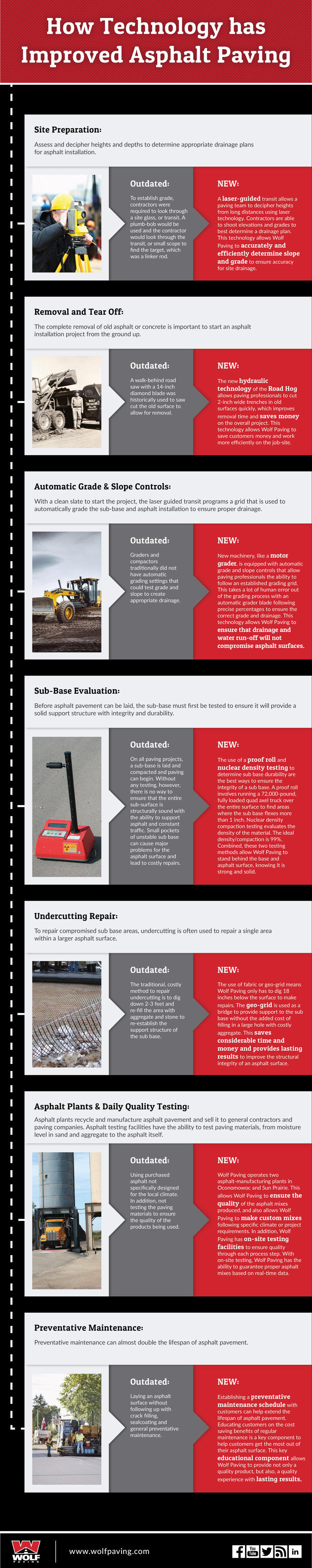

However, when it comes to the asphalt paving industry, you likely don't think about how new technology plays a role in the repair and installation process of asphalt paving. But while you get excited about the latest tablet to hit the market, we get excited about new grading and slope technology and the advancement in asphalt mixes.

Take a look below at our infographic, highlighting outdated and new approaches to asphalt pavement installation in Milwaukee, Waukesha and Madison. You may be surprised to learn about all of the amazing things our team of asphalt paving contractors at Wolf Paving can do with the new paving technology.

Site Preparation:

Assess and decipher heights and depths to determine appropriate drainage plans for asphalt installation.

Outdated: To establish grade, contractors were required to look through a site glass, or transit. A plumb-bob would be used and the contractor would look through the transit, or small scope to find the target, which was a linker rod.

New: A laser-guided transit allows a paving team to decipher heights from long distances using laser technology. Contractors are able to shoot elevations and grades to best determine a drainage plan. This technology allows Wolf Paving to accurately and efficiently determine slope and grade to ensure accuracy for site drainage.

Removal and Tear Off:

The complete removal of old asphalt or concrete is important to start an asphalt installation project from the ground up.

Outdated: A walk-behind road saw with a 14-inch diamond blade was historically used to saw cut the old surface to allow for removal.

New: The new hydraulic technology of the Road Hog allows paving professionals to cut 2-inch wide trenches in old surfaces quickly, which improves removal time and saves money on the overall project. This technology allows Wolf Paving to save customers money and work more efficiently on the job-site.

Automatic Grade & Slope Controls:

With a clean slate to start the project, the laser guided transit programs a grid that is used to automatically grade the sub-base and asphalt installation to ensure proper drainage.

Outdated: Graders and compactors traditionally did not have automatic grading settings that could test grade and slope to create appropriate drainage.

New: New machinery, like a motor grader, is equipped with automatic grade and slope controls that allow paving professionals the ability to follow an established grading grid. This takes a lot of human error out of the grading process with an automatic grader blade following precise percentages to ensure the correct grade and drainage. This technology allows Wolf Paving to ensure that drainage and water run-off will not compromise asphalt surfaces.

Sub-Base Evaluation:

Before asphalt pavement can be laid, the sub-base must first be tested to ensure it will provide a solid support structure with integrity and durability.

Outdated: On all paving projects, a sub-base is laid and compacted and paving can begin. Without any testing, however, there is no way to ensure that the entire sub-surface is structurally sound with the ability to support asphalt and constant traffic. Small pockets of unstable sub base can cause major problems for the asphalt surface and lead to costly repairs.

New: The use of a proof roll and nuclear density testing to determine sub base durability are the best ways to ensure the integrity of a sub base. A proof roll involves running a 72,000-pound, fully loaded quad axel truck over the entire surface to find areas where the sub base flexes more than 1 inch. Nuclear density compaction testing evaluates the density of the material. The ideal density/compaction is 99%. Combined, these two testing methods allow Wolf Paving to stand behind the base and asphalt surface, knowing it is strong and solid.

Undercutting Repair:

To repair compromised sub base areas, undercutting is often used to repair a single area within a larger asphalt surface.

Outdated: The traditional, costly method to repair undercutting is to dig down 2-3 feet and re-fill the area with aggregate and stone to re-establish the support structure of the sub base.

New: The use of fabric or geo-grid means Wolf Paving only has to dig 18 inches below the surface to make repairs. The geo-grid is used as a bridge to provide support to the sub base without the added cost of filling in a large hole with costly aggregate. This saves considerable time and money and provides lasting results to improve the structural integrity of an asphalt surface.

Asphalt Plants & Daily Quality Testing:

Asphalt plants recycle and manufacture asphalt pavement and sell it to general contractors and paving companies. Asphalt testing facilities have the ability to test paving materials, from moisture level in sand and aggregate to the asphalt itself.

Outdated: Using purchased asphalt not specifically designed for the local climate. In addition, not testing the paving materials to ensure the quality of the products being used.

New: Wolf Paving operates two asphalt-manufacturing plants in Oconomowoc and Sun Prairie. This allows Wolf Paving to ensure the quality of the asphalt mixes produced, and also allows Wolf Paving to make custom mixes following specific climate or project requirements. In addition, Wolf Paving has on-site testing facilities to ensure quality through each process step. With on-site testing, Wolf Paving has the ability to guarantee proper asphalt mixes based on real-time data.

Preventive Maintenance:

Preventive maintenance can almost double the lifespan of asphalt pavement.

Outdated: Laying an asphalt surface without following up with crack filling, sealcoating and general preventive maintenance.

New: Establishing a preventive maintenance schedule with customers can help extend the lifespan of asphalt pavement. Educating customers on the cost saving benefits of regular maintenance is a key component to help customers get the most out of their asphalt surface. This key educational component allows Wolf Paving to provide not only a quality product, but also, a quality experience with lasting results.

Interested in learning more about how Wolf Paving can help you?

Contact us today for a free paving estimate!

Wolf Paving offers professional paving services from Milwaukee to Madison, and everywhere in between, including all areas around: Sun Prairie, Oconomowoc and Waukesha. It’s never too early or too late to request a free paving estimate.

Call Wolf Paving today. For the Milwaukee area, call us at 262-965-2121. For the Madison area, call us at 608-249-7931.